Every year, noise-induced hearing loss affects millions of workers-often without them even noticing until it’s too late. Unlike a broken bone or a cut, this damage doesn’t hurt. It doesn’t show up on an X-ray. It creeps in slowly, quietly, and permanently. By the time you realize your ears are failing, the hair cells in your inner ear are already dead. And they don’t grow back.

This isn’t just a problem for factory workers or construction crews. It’s happening in warehouses, farms, airports, and even some offices with loud HVAC systems. The Centers for Disease Control and Prevention estimates that 22 million U.S. workers are exposed to dangerous noise levels each year. Of those, nearly 1 in 5 will develop permanent hearing loss. And here’s the worst part: noise-induced hearing loss is almost always preventable.

How Noise Kills Hearing

Your inner ear is filled with thousands of tiny hair cells. These cells move in response to sound waves and send signals to your brain. Think of them like piano strings-each one tuned to a specific pitch. When you’re exposed to loud noise, these hairs get bent, overstressed, and eventually break. Once they’re gone, your brain loses that frequency forever.

It doesn’t take a jet engine to cause damage. A lawnmower runs at 90 decibels (dBA). A power saw hits 110. At 85 dBA, the National Institute for Occupational Safety and Health (NIOSH) says your ears can handle 8 hours of exposure. But every time the noise goes up 3 dBA, your safe time cuts in half. That means at 88 dBA, you’ve got 4 hours. At 91 dBA, only 2 hours. At 100 dBA-common in construction-you’re at risk after just 15 minutes.

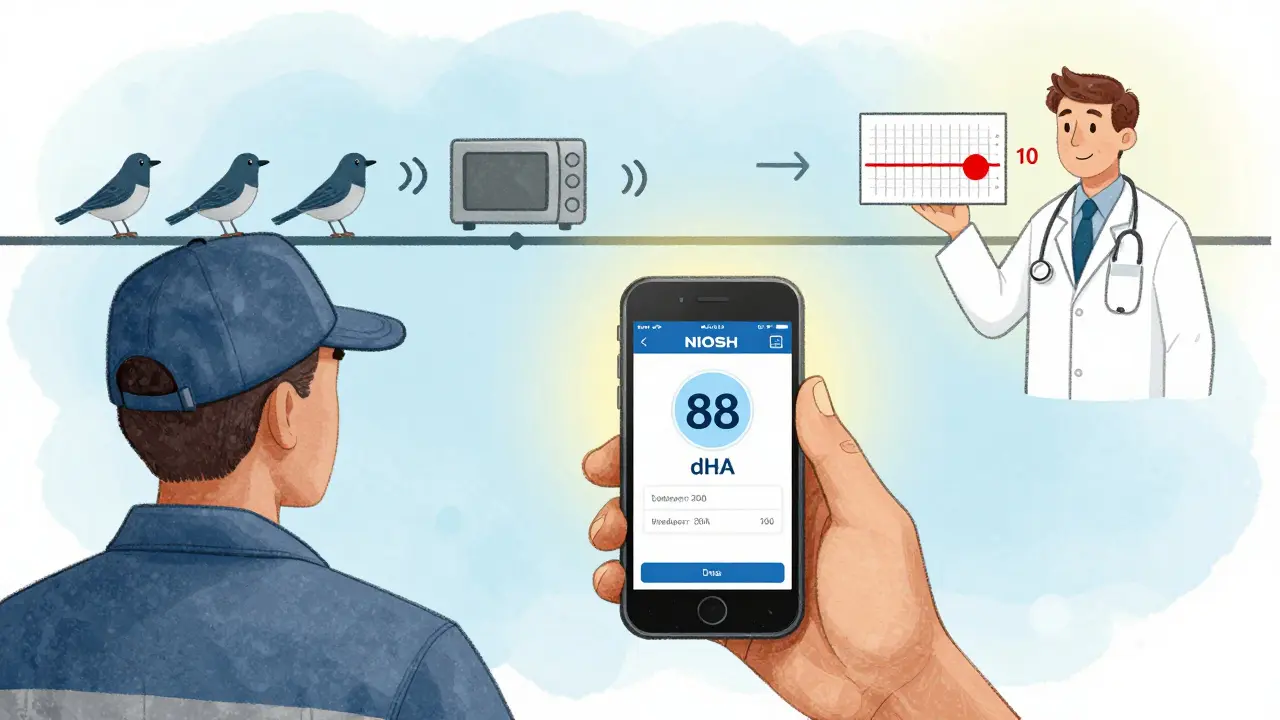

Most people don’t notice the loss right away. It starts with trouble hearing high-pitched sounds-birds chirping, children’s voices, or the beeps of a microwave. Later, conversations in noisy rooms become a struggle. By then, the damage is already done.

What the Law Says (and What It Doesn’t)

The Occupational Safety and Health Administration (OSHA) says employers must protect workers when noise hits 85 dBA over an 8-hour shift. That sounds reasonable-until you compare it to what NIOSH recommends. NIOSH says 85 dBA is already too loud. They argue that even at this level, hearing loss begins. OSHA’s rules are based on what’s technically possible to enforce, not what’s scientifically safe.

OSHA’s rules also use a 5-dB exchange rate. That means if noise goes up 5 dB, exposure time is cut in half. NIOSH uses a 3-dB rate-the same as how your ears actually work. That difference isn’t small. At 90 dBA, OSHA allows 8 hours. NIOSH says you should only be exposed for 1 hour. That’s an 8-fold difference in noise energy. And that’s why workers in the same job, under the same OSHA rules, still lose their hearing.

Europe is ahead of the U.S. The EU limits exposure to 80 dBA and requires employers to take action even before noise hits 85 dBA. California is starting to catch up. In 2023, new state rules forced employers to fix the noise at the source before handing out earplugs.

The Hierarchy of Controls: What Actually Works

When it comes to preventing hearing loss, not all solutions are equal. The best approach follows a clear order-called the hierarchy of controls. It goes from most effective to least.

- Elimination - Remove the noise source. This is ideal but rarely possible.

- Substitution - Replace loud machines with quieter ones. NIOSH’s ‘Buy-Quiet’ program now lists over 1,200 low-noise tools and machines. A quieter compressor might drop noise from 95 dBA to 82 dBA.

- Engineering controls - Install barriers, enclosures, or dampening materials. In mining, sound-dampening panels cut noise by 15-20 dBA. In factories, acoustic curtains around presses reduced exposure by 12 dBA.

- Administrative controls - Rotate workers, limit shift lengths, or schedule loud tasks for low-traffic hours. But studies show these only work about half the time because people forget or skip them.

- Hearing protection - Earplugs and earmuffs. This is the last line of defense. And it’s the most unreliable.

Too many companies stop at step five. They hand out foam earplugs and call it a day. But real-world data shows most workers don’t wear them correctly. A 2017 Cochrane review found that even though foam earplugs are rated for 30+ dB of protection, most users get only 15-20 dB because they don’t roll them properly or insert them too shallow.

Why Earplugs Often Fail

Here’s what workers actually say:

- “I take them out because I can’t hear my coworkers.”

- “These hurt after an hour.”

- “I don’t think it’s that loud.”

NIOSH’s 2021 survey found only 38% of workers wear hearing protection consistently. The top reasons? Discomfort (67%), communication issues (58%), and thinking it’s unnecessary (42%).

Custom-molded earplugs help. They’re more comfortable, fit better, and give consistent 25-30 dB reduction. But they cost $100-$200 each. Most employers won’t pay for them unless required.

Even worse, many companies give out cheap foam plugs that are reused. That’s a hygiene risk-and they lose effectiveness fast. One study found reused plugs dropped from 28 dB to 12 dB attenuation after just two days.

What a Real Hearing Conservation Program Looks Like

Successful programs don’t just hand out gear. They do five things:

- Measure noise - Use a calibrated sound level meter (Type 2 or better) to map noise levels across the worksite. NIOSH’s free Sound Level Meter app for iPhones can screen noise with ±2 dB accuracy.

- Fix the source - If a machine is over 85 dBA, try replacing it, adding a muffler, or enclosing it. Don’t wait for someone to lose hearing before acting.

- Fit-test hearing protection - Don’t just hand out earplugs. Test how well each worker’s plugs work. Real Ear Attenuation at Threshold (REAT) testing measures actual protection. Companies that do this see 50% more compliance.

- Test hearing annually - Baseline audiograms must be done within 6 months of hire. Follow-ups check for a “standard threshold shift”-a 10 dB drop at 2000, 3000, or 4000 Hz. That’s the red flag that damage is happening.

- Train workers properly - A 10-minute demo isn’t enough. Workers need hands-on training with mirrors to see how to insert foam plugs. One clinic found 75% of workers inserted them wrong the first time. After training, 90% got it right.

Companies that follow all five steps see hearing loss rates drop by 50% or more. But here’s the catch: management commitment is the biggest factor. A 2023 CDC study found 92% of successful programs had active leadership involvement. If the boss doesn’t care, the program fails.

The Hidden Cost of Ignoring Hearing Loss

Many employers think hearing protection is just a compliance cost. But the real cost is far higher.

In 2022, the Bureau of Labor Statistics recorded 19,300 cases of hearing loss that forced workers to take time off. Each claim cost an average of $14,700. That’s over $280 million in workers’ compensation payments in one year alone.

NIOSH found that for every $1 spent on a full hearing conservation program, companies saved $5.50 in reduced claims, lower turnover, and fewer accidents. Workers with hearing loss are 2.5 times more likely to have workplace accidents because they can’t hear warnings or instructions.

And then there’s the human cost. Tinnitus-the ringing in the ears-is often the first sign of damage. It affects 1 in 5 workers with NIHL. It’s constant. It’s exhausting. It ruins sleep, focus, and mental health.

What’s Changing in 2026

The tide is turning. NIOSH is pushing for a new exposure limit of 80 dBA by 2025. The European Union already lowered its action level to 80 dBA in 2024. California’s 2023 rules mean employers can’t just rely on earplugs anymore-they have to fix the noise first.

New tech is helping too. Smart earplugs like 3M’s PELTOR TS3+ now monitor noise exposure in real time and send alerts to safety managers. University researchers are testing blood biomarkers to detect early cell damage before hearing tests show anything.

But technology won’t save us if culture doesn’t change. Workers won’t protect their hearing if they’re told it’s “just part of the job.”

What You Can Do

If you work in a noisy environment:

- Ask your employer for a noise survey. If they don’t do one, request it in writing.

- Try custom-molded earplugs if foam ones hurt or fall out.

- Don’t reuse foam plugs. They lose protection and harbor bacteria.

- Report hearing problems early-even if it’s just trouble understanding speech in crowds.

- Use the NIOSH app to check noise levels at your job. If it’s over 85 dBA, it’s dangerous.

If you’re a manager:

- Start with engineering controls. Fix the machine before buying more earplugs.

- Train workers properly. Don’t skip the hands-on insertion demo.

- Let workers help pick their hearing protection. Choice increases compliance.

- Make hearing protection part of safety culture-not just a rule.

There’s no cure for noise-induced hearing loss. But there’s a simple, proven way to stop it: act before the damage starts. The science is clear. The tools exist. The cost of doing nothing is higher than the cost of prevention.

Can noise-induced hearing loss be reversed?

No. Once the hair cells in your inner ear are damaged by loud noise, they don’t regenerate. The hearing loss is permanent. That’s why prevention is the only effective strategy.

Is 85 dBA really dangerous?

Yes. While OSHA allows 85 dBA as a limit, NIOSH and other health agencies say this level still causes hearing damage over time. It’s not a safe level-it’s the threshold where damage begins. The longer you’re exposed, the worse it gets.

Do earplugs really work?

They can, but only if used correctly. Foam earplugs are often rated for 30+ dB of protection, but most people get only 15-20 dB because they don’t insert them right. Custom-molded plugs and earmuffs with proper fit-testing work better. Training and fit-testing are critical.

What industries have the highest risk?

Construction (22% of workers exposed), manufacturing (19%), mining (17%), and agriculture (15%) have the highest rates of noise exposure. But any workplace with heavy machinery, power tools, or loud engines is at risk-even warehouses and airports.

How often should I get my hearing tested?

If you’re regularly exposed to noise above 85 dBA, you should get a baseline hearing test within 6 months of starting the job. After that, annual tests are required by OSHA. Early detection of a 10 dB shift can trigger interventions before more damage occurs.

Are there quieter tools available?

Yes. NIOSH’s ‘Buy-Quiet’ initiative lists over 1,200 tools and machines that produce 3-15 dB less noise than standard models. Switching to quieter equipment is often cheaper than buying endless earplugs and managing hearing loss claims.

Amber Lane

January 22, 2026 AT 01:35My dad worked in a factory for 40 years. He never wore earplugs because he said he 'needed to hear the machines.' Now he can't hear my kids laugh. Prevention isn't optional-it's survival.

Rod Wheatley

January 23, 2026 AT 09:38THIS. So many workplaces treat hearing protection like a box to check. But real safety means fixing the noise at the source-not just handing out foam plugs and hoping for the best. I’ve seen companies cut hearing loss claims by 60% just by swapping out old compressors for quiet ones. It’s cheaper than workers’ comp. And honestly? It’s the right thing to do. 🙌

Andrew Rinaldi

January 23, 2026 AT 12:18It’s wild how we’ll spend thousands on ergonomic chairs but won’t spend $50 on proper hearing protection. We treat our backs like sacred temples but our ears like disposable gadgets. Maybe if we could hear the sound of our own hearing dying, we’d care more.

Ben McKibbin

January 24, 2026 AT 19:45OSHA’s 5-dB exchange rate is a corporate loophole dressed as regulation. NIOSH’s 3-dB standard isn’t just scientifically accurate-it’s morally non-negotiable. If you’re still using OSHA’s outdated metrics to justify worker exposure, you’re not managing risk-you’re managing liability. And that’s not leadership. It’s negligence with a badge.

Dee Monroe

January 26, 2026 AT 02:41I used to think noise-induced hearing loss was just something that happened to ‘other people’-the loud machinery guys, the construction crews. Then I started noticing how hard it was to hear my coffee machine beep, or my phone notification in a crowded room. I didn’t even realize I was losing it until I missed my daughter saying ‘I love you’ twice because the AC was running. It’s not dramatic. It’s quiet. And that’s why it’s so dangerous. We don’t feel it until it’s too late. But here’s the good part: it’s preventable. You don’t need a miracle. You need awareness. You need to care enough to ask: ‘Is this noise really necessary?’ And if the answer is no-then fix it. Not tomorrow. Not next quarter. Now. Because your ears aren’t replaceable. And neither is your ability to hear the people you love.

michelle Brownsea

January 27, 2026 AT 21:06How is it still legal to let employers hand out single-use foam earplugs that degrade after 48 hours? That’s not safety-it’s a scam. And the fact that most workers don’t even know how to insert them properly? That’s not negligence-it’s systemic abuse. If your company hasn’t implemented REAT testing, you’re not protecting your employees-you’re just hoping they don’t sue you later.

Stephen Rock

January 29, 2026 AT 10:07Stop acting like earplugs are the solution. They’re a bandaid on a bullet wound. The real problem? Bosses who care more about budgets than decibels. And workers who think ‘it’s just noise’ because they’ve been desensitized for years. Wake up. Your hearing isn’t a perk. It’s your birthright.

Melanie Pearson

January 31, 2026 AT 01:19While I appreciate the sentiment, I must point out that the NIOSH guidelines are not legally binding, and OSHA regulations are the only enforceable standards in the United States. To suggest that employers are violating ethical norms by adhering to OSHA’s 85 dBA threshold is misleading. Compliance with federal law should not be conflated with moral failure. Furthermore, the cost of custom-molded earplugs for every employee is not fiscally responsible for small businesses. A balanced, pragmatic approach is required.

lokesh prasanth

February 1, 2026 AT 09:05in india we dont even have noise laws for factories. workers just deal with it. i work in a textile mill and my ears ring all day. no one cares. why should they? we are cheap labor. if your ears die, you get a new job. thats how it works here.

MAHENDRA MEGHWAL

February 3, 2026 AT 05:21As a safety officer in a manufacturing plant in India, I can confirm that the absence of regulatory enforcement does not absolve us of ethical responsibility. We have implemented a voluntary noise reduction program, including engineering controls and custom-fit hearing protection, funded through operational savings from reduced absenteeism. The human cost of hearing loss transcends borders, and compassion must not be contingent upon legislation.

Gerard Jordan

February 4, 2026 AT 18:55Just had a worker come up to me after reading this and say, ‘I didn’t know I could ask for better earplugs.’ 🥺 I got him fitted with custom ones today. He cried. Said he could hear his granddaughter say ‘hi’ again. This isn’t about compliance. It’s about connection. 💙